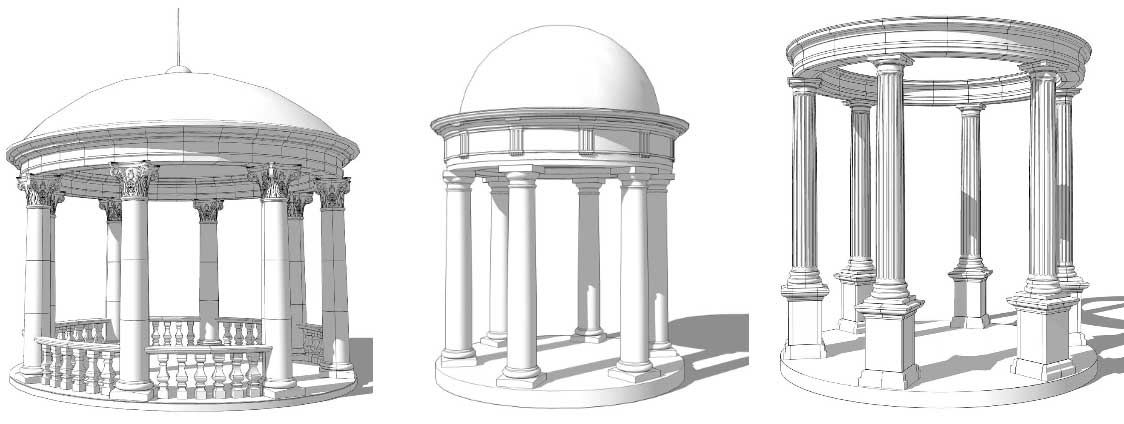

Rotundas, known for their circular design and domed roofs, have been a popular architectural feature since ancient times. Traditionally constructed from heavy, durable materials such as stone or brick, the modern era demands more lightweight and versatile solutions. Enter the innovative combination of expanded polystyrene (EPS) with reinforcement and a protective layer for painting. This article explores the benefits and production process of these lightweight, yet durable rotundas.

EPS: A Versatile Building Material

Expanded polystyrene (EPS) is a lightweight, closed-cell foam material derived from petroleum. Its unique properties, such as low density, high strength-to-weight ratio, and excellent insulation capabilities, have made it a popular choice in various industries. In the construction sector, EPS has been used for insulation, void filling, and even structural elements. However, recent advancements have allowed its use in more complex architectural features like rotundas.

Reinforcement: Enhancing Durability and Structural Integrity

To provide the necessary strength and durability for a rotunda, EPS is combined with a reinforcement material. This is typically achieved using fiberglass mesh or steel fibers. The reinforcement is embedded within the EPS structure, enhancing its load-bearing capacity, tensile strength, and overall durability. As a result, the rotunda can withstand the stresses and strains experienced in everyday use.

Protective Layer for Painting: Ensuring Aesthetic Appeal and Longevity

The final step in creating a lightweight, durable rotunda is applying a protective layer to the EPS-reinforced structure. This layer serves multiple purposes:

- Protection: The protective layer shields the EPS from damage caused by UV radiation, moisture, and other environmental factors, extending its lifespan.

- Aesthetic appeal: The layer provides a smooth, even surface that can be painted in various colors and designs, allowing architects and designers to customize the rotunda’s appearance.

- Additional reinforcement: Some protective layers, like polymer-modified cementitious coatings, can provide added strength and durability to the rotunda structure.

The Production Process: Constructing a rotunda from EPS with reinforcement and a protective layer involves the following steps:

- Design: The rotunda’s dimensions and features are designed using computer-aided design (CAD) software. The design is then used to create a mold for the EPS components.

- EPS molding: The mold is filled with expandable polystyrene beads, which are heated and expanded to form the rotunda’s structural components. The reinforcement material is embedded within the EPS during this stage.

- Assembly: The EPS components are assembled on-site, creating the complete rotunda structure. Joints between components are sealed with adhesive to ensure airtightness and structural integrity.

- Application of the protective layer: The protective coating is applied to the entire surface of the rotunda, ensuring even coverage and thickness.

- Painting and finishing: Once the protective layer has cured, the rotunda is painted and decorated as desired, providing the finished product with a unique and aesthetically pleasing appearance.

The combination of EPS, reinforcement, and a protective layer for painting has revolutionized the production of rotundas, offering a lightweight and durable alternative to traditional construction materials. This innovative approach not only reduces the overall weight and complexity of the structure but also provides architects and designers with greater flexibility in creating unique, eye-catching rotundas that stand the test of time.